UBC and Wet’suwet’en First Nation collaborate to create new packaging foam from wood waste

A new biodegradable packing foam developed at UBC not only potentially addresses the world’s plastic pollution crisis but also serves as an equal and true partnership example of working with First Nations.

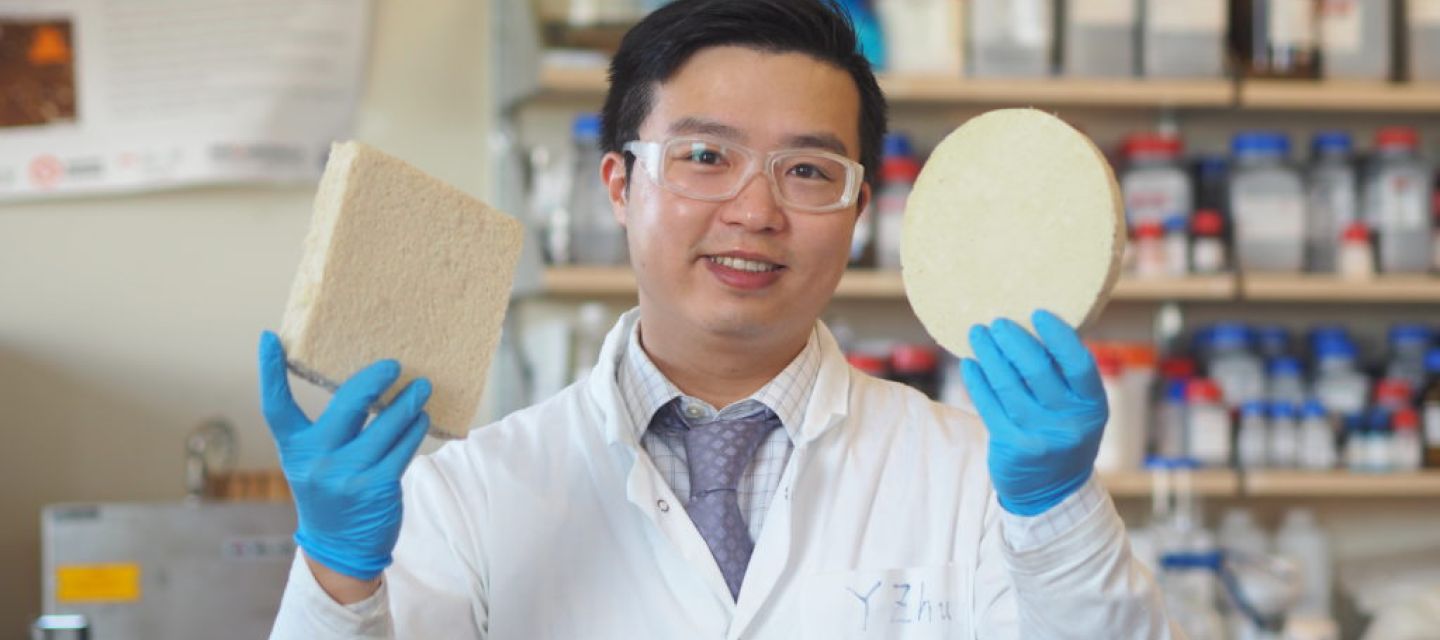

The team came together to turn a timely research idea into reality while helping solve a critical community need at the same time: UBC researchers Dr. Feng Jiang and postdoctoral fellow Dr. Yeling Zhu, Reg Ogen and Joe Wong, president and CEO and vice president respectively of Wet’suwet’en First Nation’s Yinka Dene Economic Development Limited Partnership, and the office of the Chief Forester in the Ministry of Forests.

Transforming waste into pollutant-free innovation

Dr. Jiang, an assistant professor in the UBC faculty of forestry and the Canada Research Chair in Sustainable Functional Biomaterials, started developing a “biofoam” many years ago both to find new uses for wood waste and reduce pollution from packaging foam.

“Styrofoam waste fills up to 30 per cent of global landfills and can take more than 500 years to break down. Our biofoam breaks down in the soil in a couple of weeks, requires little heat and few chemicals to make, and can be used as substitute for packaging foams, packing peanuts and even thermal insulation boards,” says Dr. Jiang.

He adds that the project also helps repurpose wood waste that is often left behind after trees are harvested. “Less than 50 per cent of harvested trees are used in the wood industries—the rest is left behind in the forest, serving as potential fuel for devastating wildfires.”

Wet’suwet’en First Nation band and UBC form partnership

One year into the project, Dr. Jiang met Reg Ogen and Joe Wong at an event organized by the Ministry of Forests’ Innovation, Bioeconomy and Indigenous Opportunities Branch. A partnership was born.

“Our Nation was trying to create a new economy out of what was left of our forest after the wildfires and the damage caused by the mountain pine beetle epidemic in the 1990s and early 2000s. The amount of timber available for harvest in the next 20 to 60 years was significantly reduced. I have often asked why, when trees are harvested, up to 50 per cent of the tree is left behind to just burn. As a Nation, we were also concerned about the losses in habitat, water quality, decline in moose and salmon populations and the acceleration in climate change,” recalls Ogen.

“When I met Dr. Jiang, I knew we wanted to work with him on this journey of creating the Wet’suwet’en forest bioeconomy, so that we could use what’s left of our forests, and maybe also be able to help other communities—including the fin species and four-legged animals.”

Two years of collaboration followed, with Yinka Dene Economic Development helping to secure provincial government funding and providing raw materials from their forests, located near Burns Lake, B.C. for the research.

With biofoam development now completed, the team is putting together a business model, with plans to open a pilot plant in B.C.

Sharing intellectual property forges meaningful partnership

“A unique feature of this project is that the intellectual property is shared between UBC and First Nations,” says Dr. Jiang. “This project highlights the benefits of forging meaningful partnerships by first identifying the problems—reducing waste from each tree harvested, mitigating the impacts of wildfires, and ensuring participation in the forest sector by First Nations—before moving towards a solution with First Nations as a true partner.”

Ogen adds: “Status quo forestry industrial activities impact First Nations the most because we are losing our pharmacies, places of worship, areas for supporting cultural narratives and supermarkets. Climate change is accelerating our losses. This is why I felt it is important we find a partner, like Dr. Jiang’s lab at UBC, with support from the team at the Chief Forester’s office, to create a forest bioeconomy and seek solutions to mitigate climate change and reduce our reliance on fossil fuel-based products, especially in the construction and packaging sectors.”